Project Peregrine is an autonomous fixed-wing Unmanned Aerial Vehicle (UAV) that employs thrust vector control to achieve exceptional maneuverability within confined airspace, while harnessing the advantages inherent to fixed-wing aircraft. In the realm of modern military surveillance drones, a prevailing distinction exists between two predominant categories. The first category comprises slow, quadcopter-style devices noted for their agility in tight spaces but often characterized by their conspicuous noise output. The second category encompasses large, runway-dependent aircraft that necessitate specialized launching mechanisms and sensitive camera equipment to compensate for their operational distance from the target, essential for maintaining stealth.

To bridge the gap between these two distinct UAV types, Peregrine introduces a three-stage flight strategy. In the first stage, thrust vectoring technology, commonly employed in rocketry for vertical stabilization during takeoff at low speeds, facilitates runway-independent ascent, allowing the UAV to attain velocity and altitude. Stage two initiates once the UAV has achieved the desired altitude within the geographic range of its surveillance objective. During this phase, the UAV executes a controlled nosedive, reaching terminal velocity and closing the gap with the target area. Stage three seamlessly follows stage two, where the UAV disengages its propulsion, achieving complete silence. In this phase, the UAV relies on its wings to glide at low altitude over the target area, leaving no acoustic footprint.

3D printing played a pivotal role in manufacturing Peregrine's mechanical components, offering a precise and customized approach that allowed for the creation of intricate parts, aligning with contemporary manufacturing techniques in the development of the project.

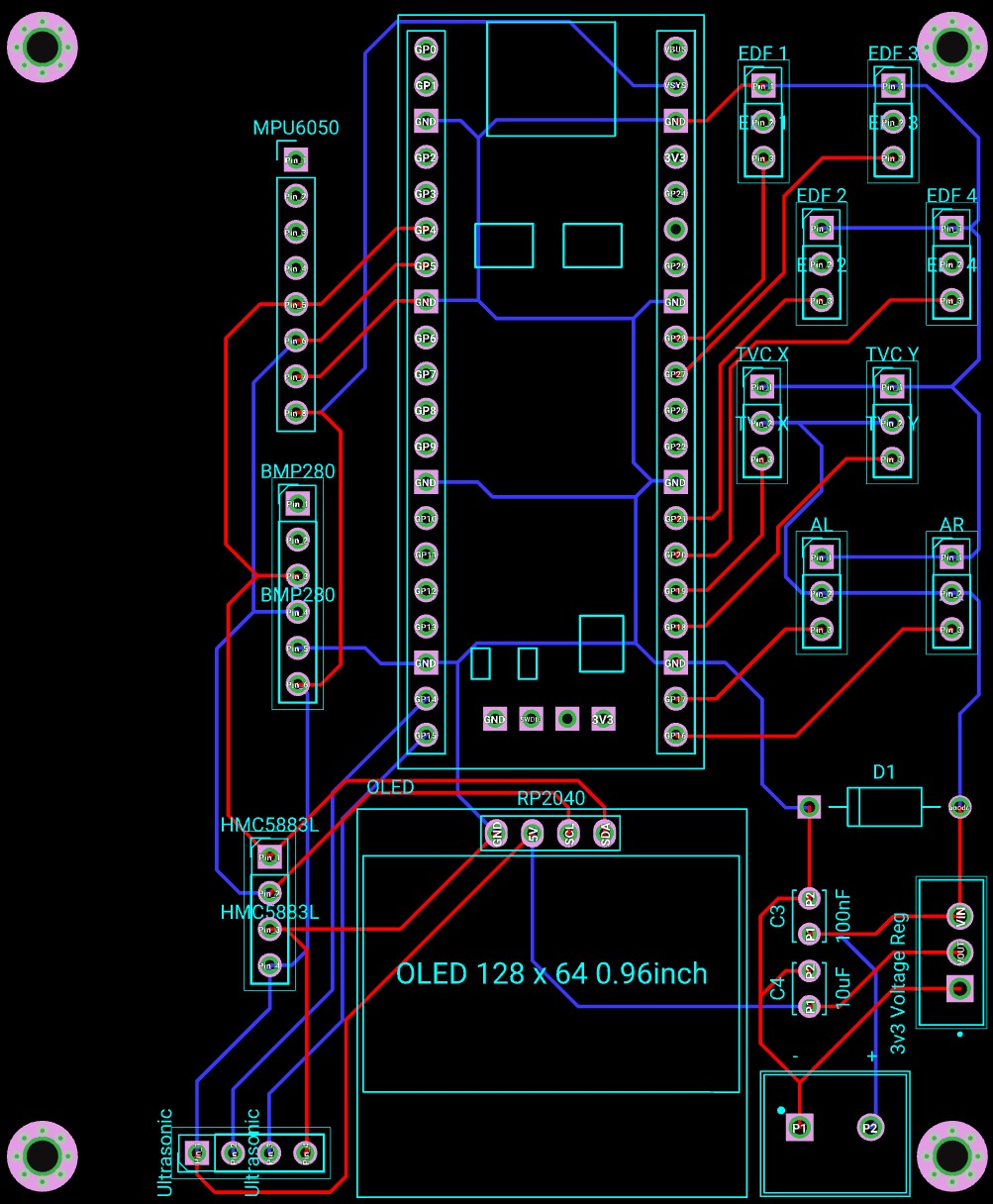

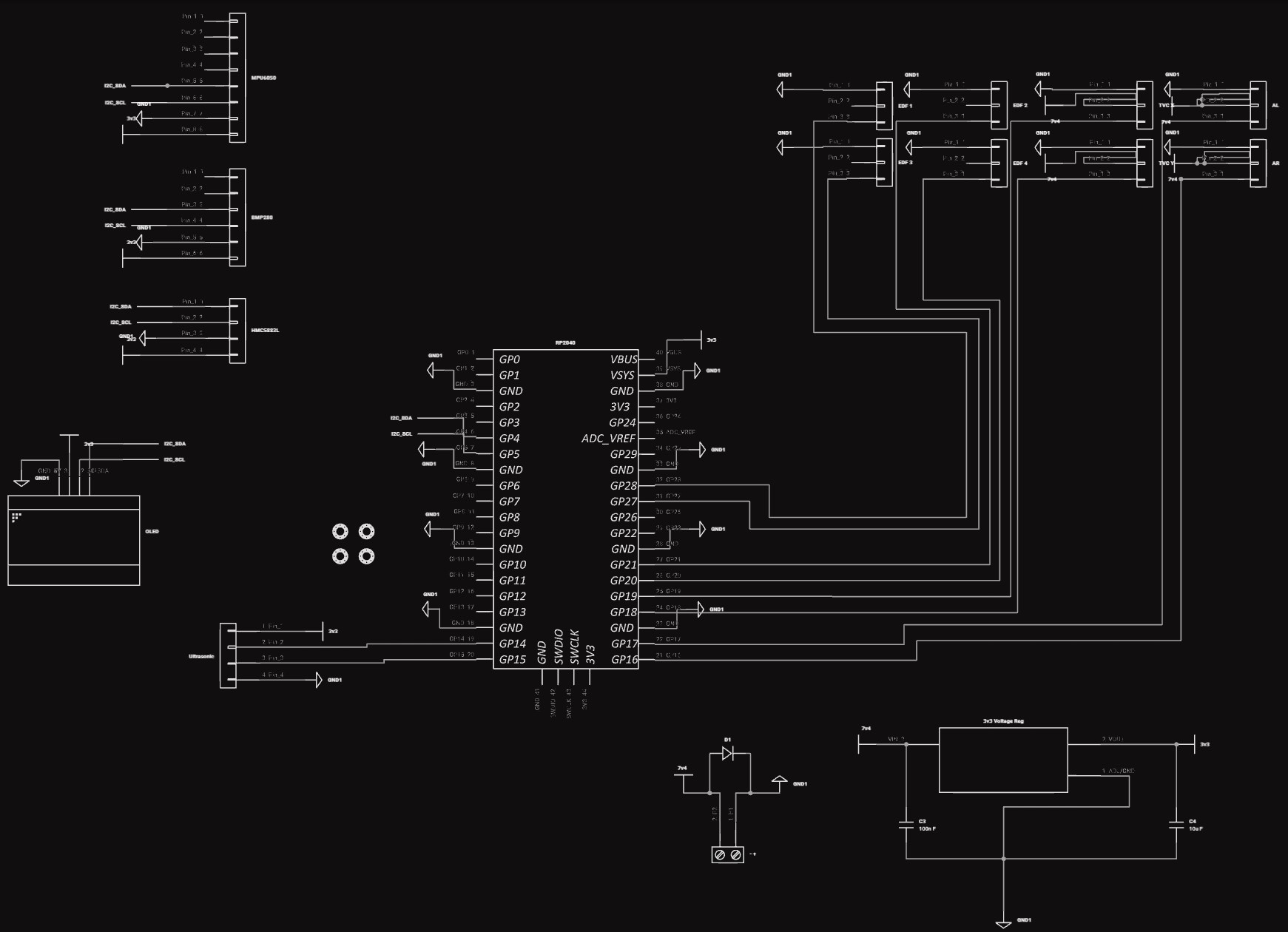

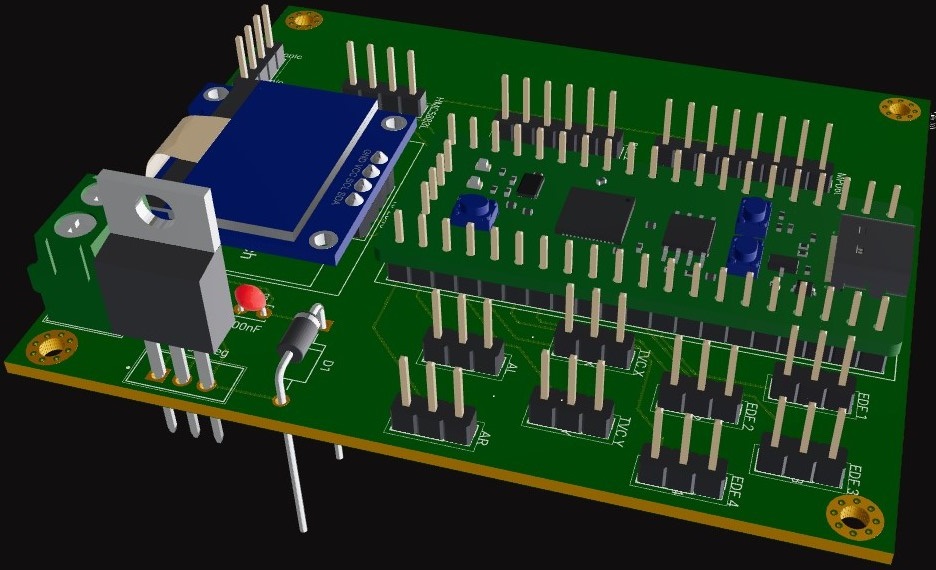

Flux.ai was used to generate the PCB (Printed Circuit Board) design as it allowed for a easy cloud-based solution for electrical design.

Learn More- Raspberry Pi Pico W

- ARM M0+ Dual Core Microcontroller

- MPU6050

- 6-axis Accelerometer / Gyroscope

- BMP280

- Barometric Pressure Sensor

- HMC5883L

- 3-axis Magnetometer

- SSD1306

- OLED Display

- *various power regulation components*

PCBWay was used to manufacture all of the PCB boards through 4 iterations as they provided quick and timely manufacturing.

Learn MoreDedicated to perfection, I iterated through four designs using Flux.ai PCB design software, sculpting the ideal printed circuit board for my UAV

The ARM Cortex-M0+ microcontroller powers the UAV's embedded system. Unlike traditional programming, embedded systems require meticulous attention to hardware constraints, real-time responsiveness, and low-level optimizations.

Learn More- Sensor Reading and Data Processing / Filtering

- Motion Control:

- Implements PID for precise control of the UAV's movements.

- Error Recovery:

- Detects and handles errors to maintain operational integrity.

- Utilizes hardware watchdog for multi-level failover

- Dynamic Mission Configurations:

- Allows for on-the-fly adjustments to mission parameters based on changing conditions.

- Highspeed Reliable C2 Communication:

- Facilitates fast and reliable communication between the UAV and Peregrine C2

- State Recovery:

- Recovers from unexpected states or disruptions to maintain stability and functionality.

- Smart Motor Control:

- Utilizes intelligent algorithms for optimal motor performance and energy efficiency.

Utilizes FreeRTOS, a real-time operating system, to efficiently manage tasks, scheduling, and resource allocation, ensuring smooth and reliable operation of the UAV's software components.

Learn More